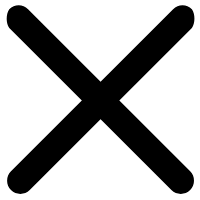

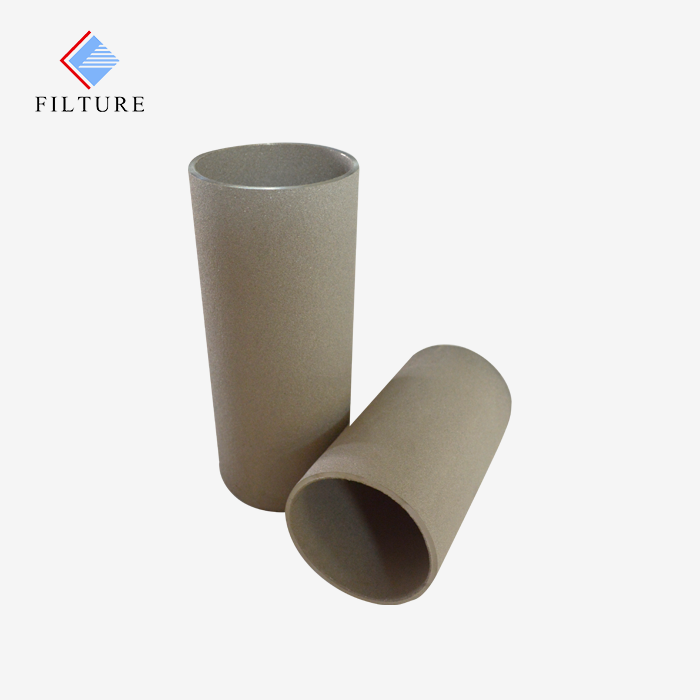

sintered stainless steel filter elements

Absolute Rate :Cleanable

Available Sizes:

Outer Diameter: 60mm(2.36")

Length:

254mm(10")

508mm(20")

762mm(30")

1016mm(40")

Micron Rating: 0.22-100um

- Product Description

Sintered Stainless Steel Filter Elements: High-Performance Solutions for Industrial Applications

Sintered stainless steel filter elements are engineered for high-performance filtration in a variety of industries. Known for their resistance to extreme conditions, these filters are highly durable, efficient, and versatile, making them ideal for applications that demand reliability under high temperature, pressure, and corrosive environments. With excellent structural stability, these filters are designed to last and perform consistently, meeting the needs of industries such as aerospace, energy, pharmaceuticals, and chemical manufacturing.

Technical Specifications

Here’s a quick overview of the key technical specifications for our products. This table provides detailed data to help you choose the right product for your specific requirements.

| Parameter | Value |

|---|---|

| Material | Stainless Steel (SS316L, SS304, etc.) |

| Pore Size Range | 0.5 to 100 microns |

| Filtration Efficiency | Up to 99.99% |

| Operating Temperature | -200°C to 800°C |

| Operating Pressure | Up to 50 bar (700 psi) |

| Porosity | High porosity for improved fluid flow |

| Durability | High impact and corrosion resistance |

| Shape | Customizable (cylindrical, disc, pleated) |

|  |  |  |

|  |  |  |

Product Features

Strength & Reliability:

The items are outlined for extraordinary solidness and long benefit life. They can withstand tall temperatures (up to 800°C) and tall weights, which makes them reasonable for indeed the most challenging mechanical conditions.

High-Performance Filtration:

With a tall porosity structure and exact pore measure, these channels convey uncommon filtration proficiency, guaranteeing that debasements are evacuated viably whereas permitting ideal liquid flow.

Corrosion Resistance:

Made from stainless steel, these channels are safe to destructive situations, making them appropriate for utilize in businesses such as chemical preparing, petrochemical, and nourishment and refreshment manufacturing.

Easy Upkeep & Reusability:

These channels are simple to clean and keep up, decreasing operational downtime and upkeep costs. Their vigorous development permits them to be reused different times, guaranteeing a cost-effective arrangement for long-term utilize.

Applications

Sintered stainless steel filter elements are used in a wide variety of applications across different industries:

- Petrochemical Industry: For filtration of oils, gasses, and chemicals in cruel environments.

- Pharmaceutical Industry: Guarantees tall guidelines of cleanliness and immaculateness, basic for sedate manufacturing.

- Food & Refreshment: Utilized for fluid filtration, guaranteeing item security and quality.

- Aerospace: Channels for discuss and liquid frameworks that require lightweight, solid components.

- Energy & Chemical Businesses: Basic for liquid and gas filtration in high-pressure and high-temperature frameworks.

These filters are ideal for fine filtration, separation, and purification applications where high efficiency, reliability, and durability are paramount.

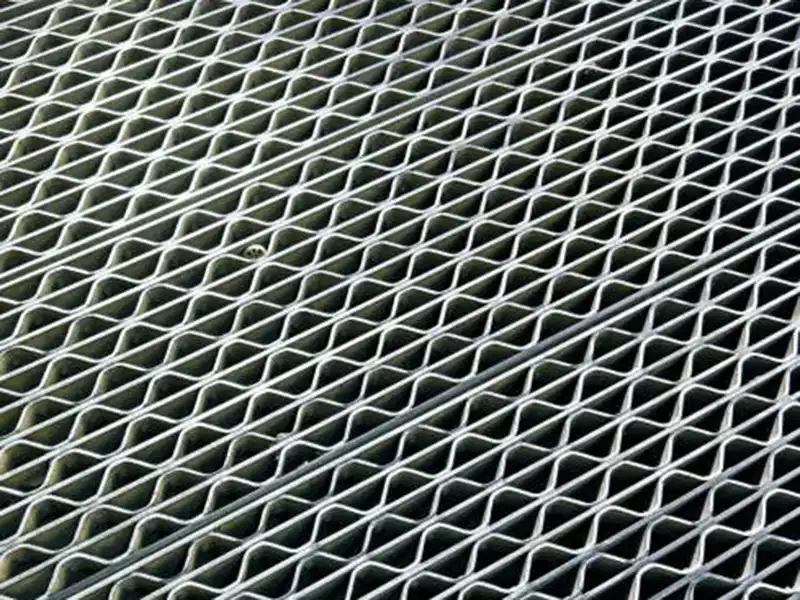

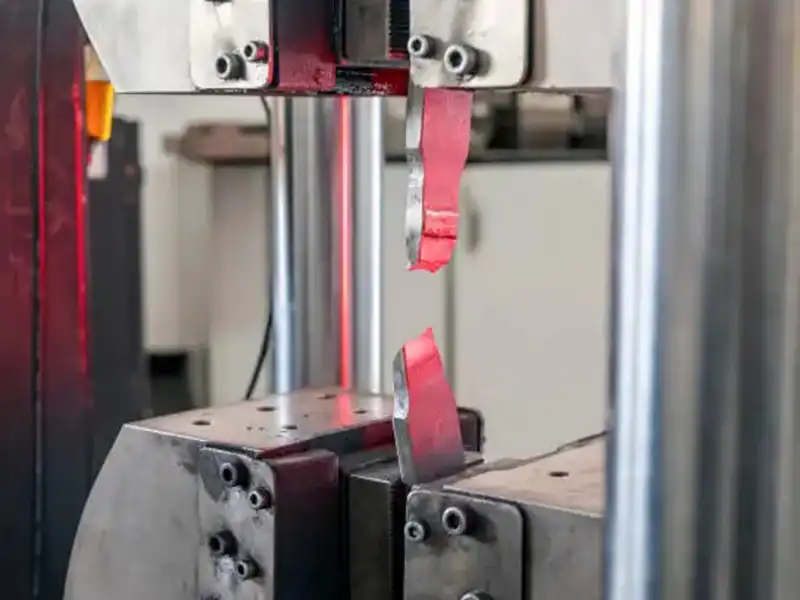

Manufacturing Process

The product is created through a specialized sintering process that fuses fine metal powders at high temperatures, resulting in a filter with consistent porosity and structural integrity. The sintered structure ensures superior strength and longevity, making it ideal for high-demand applications.

Process Highlights:

Multi-Layer Structure: Some variants feature multi-layer construction for enhanced filtration efficiency and strength.

Custom Molding: Tailored to meet specific filtration needs, offering flexibility in pore sizes, materials, and dimensions.

Raw material preparation

Titanium, Stainless Steel powder

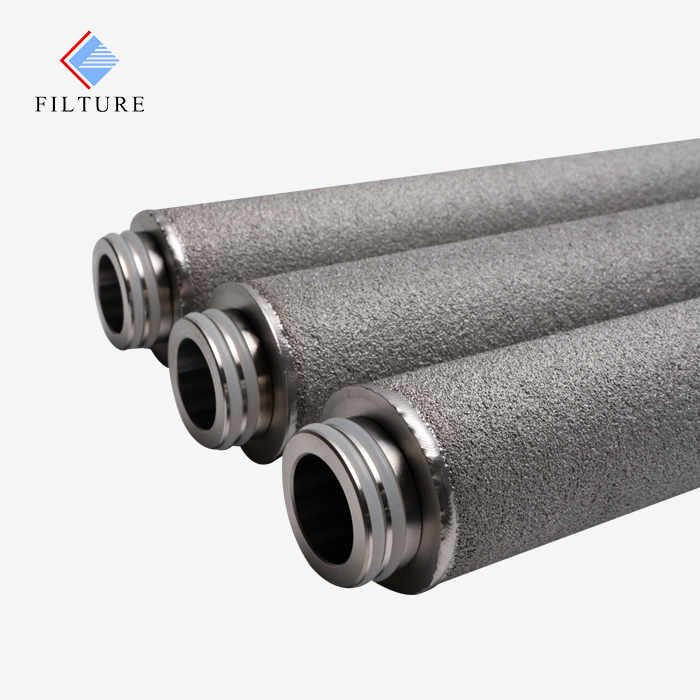

Metal Mesh

Titanium and Stainless Steel metal fibers

Molding process

Pressing

High temperature sintering

Welding

Customization Options

We offer full customization of the products, allowing you to tailor the following features based on your specific requirements:

- Size: Custom dimensions to fit your equipment.

- Shape: Cylindrical, disc-shaped, or pleated formats.

- Material: Options including stainless steel, titanium, and nickel alloys.

- Pore Size: Select from a wide range of pore sizes to meet filtration needs.

Our flexible production capabilities ensure we can meet the needs of industries with specialized requirements.

Quality Assurance

We uphold rigorous quality control processes to ensure that every filter element meets the highest standards. Our products are manufactured in compliance with international certifications such as ISO 9001, and CE, ensuring that they perform reliably in all operational conditions. Each filter undergoes comprehensive testing to guarantee efficiency, durability, and safety.

Packaging and Logistics

Our products are carefully packaged to prevent any damage during shipping. We ensure timely delivery worldwide through our reliable logistics partners, with flexible shipping options to meet international customers’ needs. Whether you are based in Europe, North America, or Asia-Pacific, we ensure your order arrives safely and on time.

Customer Support

We are committed to providing exceptional customer support, from pre-sales consultation to after-sales service. Our technical team is available to guide you through product selection, installation, and maintenance, ensuring optimal performance. Contact us for any questions or assistance at sam.young@sintered-metal.com or via Tel/Whatsapp: +8615877694221.

Why Choose Us?

With years of experience and a strong focus on innovation, we specialize in producing high-quality products that meet the diverse needs of our global customers. Our commitment to customization, product quality, timely delivery, and exceptional customer service sets us apart as an industry leader. We work closely with each client to provide tailored solutions that ensure long-term reliability and efficiency.

OEM Services

We provide OEM services for products, allowing you to manufacture products according to your exact specifications. From size and shape to material and pore size, we can customize every aspect to meet your unique needs.

Frequently Asked Questions (FAQs)

Q: What industries use sintered stainless steel filter elements?

A: Our filters are widely used in petrochemical, pharmaceutical, food and beverage, aerospace, and energy industries.

Q: How do I choose the right sintered filter element for my needs?

A: Consider factors such as the filtration requirement, operating temperature, pressure, and corrosion resistance. Our technical team can assist with product selection.

Q: Can these filters be reused?

A: Yes, sintered stainless steel filters are highly durable and can be cleaned and reused multiple times.

Contact Us

For more information or to request a quote, feel free to reach out to us directly:

Email: sam.young@sintered-metal.com

Tel/Whatsapp: +8615877694221

Our team is ready to assist you with your filtration needs and provide customized solutions to meet your unique requirements.

VIEW MORETitanium sintered filter elements

VIEW MORETitanium sintered filter elements VIEW MOREsintered stainless steel steam filter element

VIEW MOREsintered stainless steel steam filter element VIEW MOREhigh quality titanium filter element

VIEW MOREhigh quality titanium filter element VIEW MOREtitanium cartridge filter element

VIEW MOREtitanium cartridge filter element VIEW MOREsterile titanium filter element

VIEW MOREsterile titanium filter element VIEW MOREsintered stainless

VIEW MOREsintered stainless VIEW MOREss sintered filter

VIEW MOREss sintered filter VIEW MOREsintered filter elements

VIEW MOREsintered filter elements

_1742364652633.webp)